Gamma Column Scanning

Online Gamma Scanning of Column

Auto-Column-Scanner is in use in the field

Malfunctioning distillation column can result in a large financial loss due to off-spec product, loss of production or unexpected shut down of the plant.

How to troubleshoot?

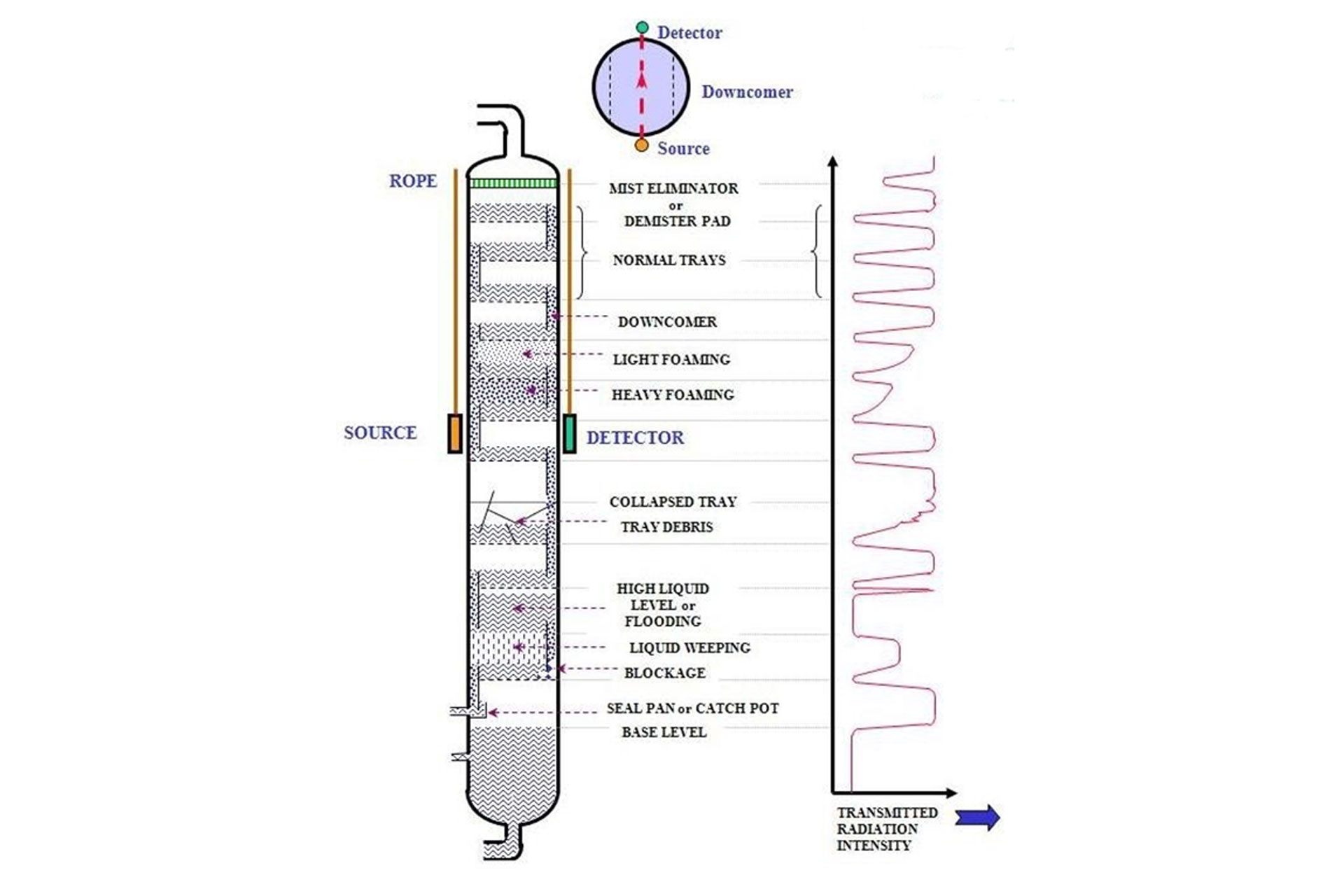

- Gamma - Ray Scanning is a most convenient, cost- effective, fast, efficient, and non-intrusive technique to examine inner details of a column, while it is in online operation.

Column scanning allows an engineer to study tray or packing hydraulics inside a column at any set of online condition. It provides essential data to optimise the performance of vessels, extend column run times, track the performance-deteriorating effects of fouling and solids deposition, and identify maintenance requirements well in advance of scheduled turnarounds.

This on-line knowledge can reduce repair downtime significantly. By analysing the scanning results, a number of common malfunctions in trayed or packed bed vessels can be determined.

Can be used to

- Assess hydraulic performance using relative density differences

- Debottleneck columns and units

- Monitor response to operating changes

- Pre-turnaround detection of tray and packing replacements

- Verify placement of trays, packed beds and distributors

- Evaluate the quality of liquid phase distribution

- Evaluate tray froth heights

- Detect mechanical, rate and process related problems

- Detect fouled or crushed packing, overflowing distributor and collector trays, flooding foaming or vapour induced maldistribution

Crude Distillation Tower

| Height | 44 m |

|---|---|

| Diameter | 4.3 m |

| Insulation thk. | 100 mm |

| Single wall thk | 25 mm |

| Number of trays | 55 |

| Tray spacing | 686 mm |

| Tray weir height | 51 mm |

| Temperature | 360o C |

| Pressure | 4.218 kg/cm2 |

Auto-column-scanner is in use in the field